Why tinking about Tilting Head Technology?

Tilting head technology is a “must have” solution for maximum flexibility in automatic grinding applications.

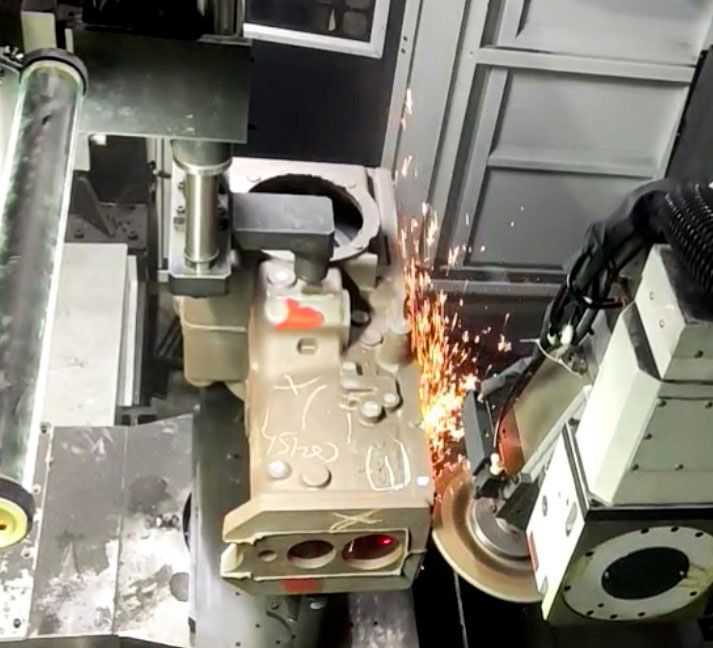

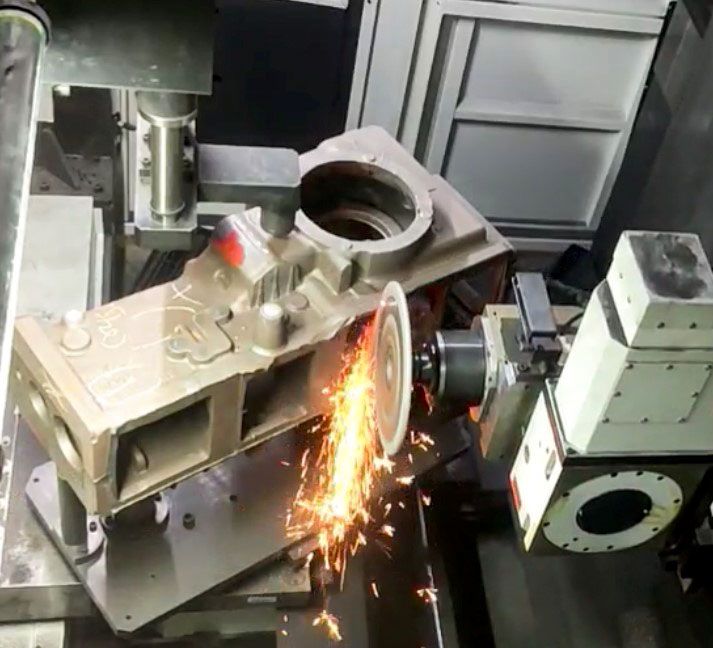

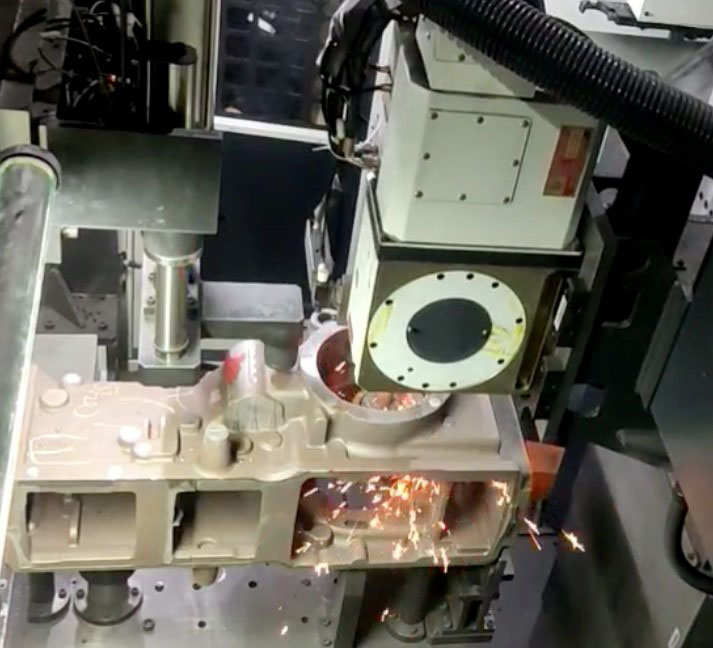

The combination of the 3 linear axes, the rotary axis B and the ability to angle the tool offers the user a full 5 axis machine that guarantees the best finishing of the castings.

Plus of Tilting Head Technology

- Compared to a robotic solution where the spindle is mounted on the robot wrist, as weak as it can be far from the robot base, our tilting head is mounted very close to the LM guides with a very rigid design verified through FEM analysis, giving the maximum performance in terms of rigidity at every working angle.

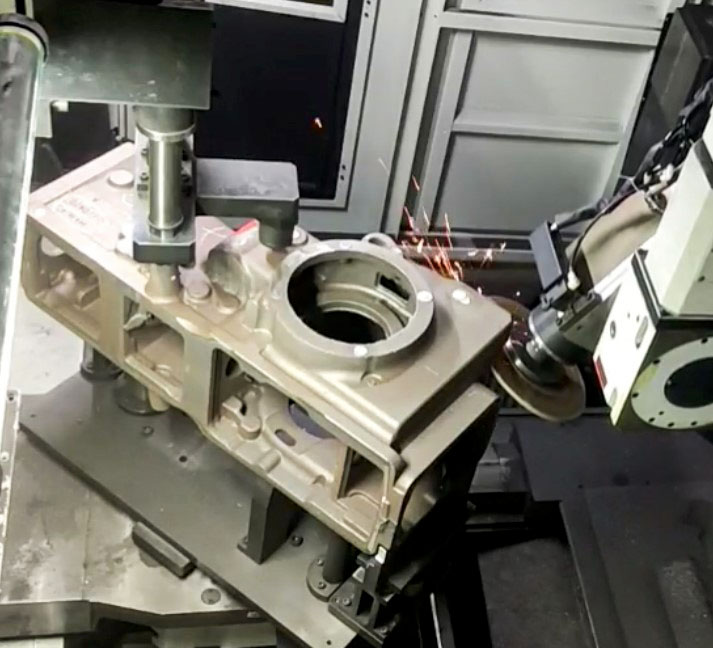

- Using long tools it is possible to reach and finish internal areas of large castings very easily, taking also advantage of the interpolation of the different axes.

- The high power offered by the single water-cooled electro spindle allows best performances with each chosen tool, unlike other solutions where very low power motors are used to drive the secondary tools.

The tilting table is a controlled axis managed directly by the CNC system of the machine, therefore able to work at any required degree and to interpolate with other axis if required.

The machine configuration comes as standard with two tools on the same spindle and as an option with single tool and automatic tool change whenever high flexibility is needed.