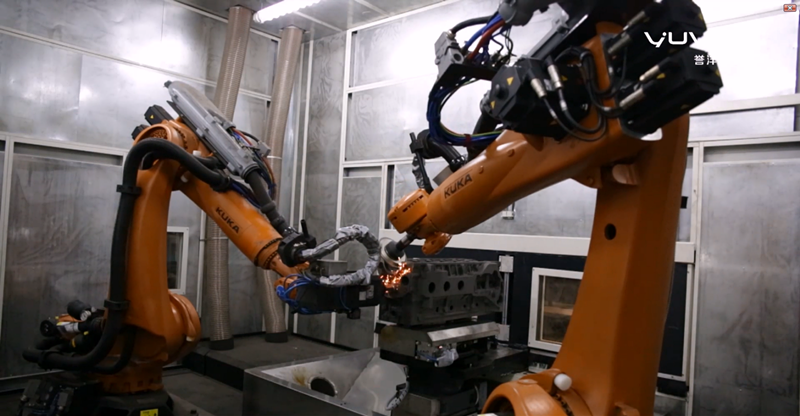

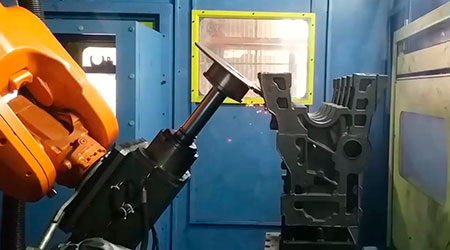

Cells designed to allow a high percentage of automatic finishing or for the automatic grinding on large pieces. The robot can be used to move the grinding tool around the part or to move the piece against the grinding tool, depending on the needs of the individual customer.

Sectors

Robotic grinding cells – product portfolio

| Model | GG 210 | GT 210 | GTD 210 | GT 300 | GT 500 |

|---|---|---|---|---|---|

| Working area (*) Dia. x H. |

900 x 500 mm40″ x 19.6″ |

900 x 750 mm40″ x 29.5″ |

1450 x 800 mm64.5″ x 31.4″ |

2100 x 600 mm82.6″ x 23.6″ |

3000 x 1000 mm118″ x 39.3″ |

| Max payload (*) |

150 Kg330 lbs |

300 Kg660 lbs |

400 Kg880 lbs |

600 Kg1320 lbs |

1500 Kg3300 lbs |

(*) part + fixture

Main features

Part quick loading

The castings loading and unloading is usually performed by means of a two-position pallet, with outside manual loading area controlled by safety barriers that stop the pallet changer rotation if interrupted accidentally by the worker. The pallet changer system automatically loads the raw part and download the ground part in just few seconds. When the part is inside the machine a pneumatic tailstock clamps it on the fixture assuring stable grinding operation.

Optionally other loading systems can be offered (belt conveyor, drawers and so on).

Laser measuring device

After been loaded inside the working area the part is automatically checked by the laser measurement system to verify its real location on the jig and its dimensional deviations compared to the masterpiece. The grinding program is then automatically adjusted according to the laser readings granting a consistent finishing quality for all the pieces produced.

7 axis grinding

After the part is checked by the laser the grinding cycle starts. The electro spindle carrying the grinding tools is mounted on a robotic arm for optimal positioning of the tool in the space. The standard electro spindle carries two tools (one large wheel and a small cutter). Totally the cell has 7 controlled axes granting maximum flexibility and best automatic finishing of the grinding process.

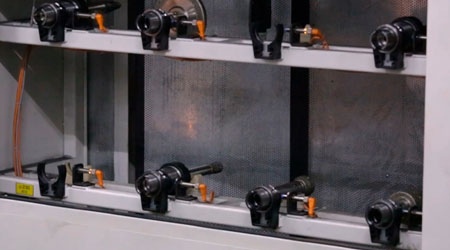

Tool magazine

Optionally the machine can be equipped with automatic tool changer and a tool magazine. In this way, for each part to be ground, dedicated tools can be used in order to maximize the automatic finishing level, with tool change done automatically in just few seconds.

With this unique option the machine grants also best performances in terms of OEE thanks to the worn-out tool replacement in very short time.